Companies across industries rely on accurate measurements to maintain quality standards, reduce waste, and stay competitive in global markets. While traditional measurement methods served their purpose for decades, the digital age demands smarter solutions that streamline processes without sacrificing accuracy.

Mitutoyo calipers represent the gold standard in precision measurement tools, and the ability to integrate them seamlessly with data collection systems opens up entirely new possibilities for manufacturers. This integration transforms how companies collect, analyze, and act on measurement data, creating workflows that are both more efficient and more reliable than traditional manual methods.

The combination of high-quality measurement instruments with sophisticated data collection capabilities addresses several challenges that modern manufacturers face daily. From reducing human error in data entry to creating comprehensive quality control records, integrating Mitutoyo calipers with your data collection systems brings a score of benefits that can take your operation to the next level.

The Advantage of Mitutoyo Calipers

Mitutoyo calipers have earned their reputation as industry-leading measurement tools through decades of innovation and reliability. These precision instruments measure dimensions with exceptional accuracy, making them indispensable in manufacturing environments where even microscopic variations can impact product quality and performance.

Manufacturing industries depend on Mitutoyo calipers because they deliver consistent, repeatable measurements across a wide range of applications. From automotive components that must meet strict tolerance requirements to aerospace parts where precision can mean the difference between success and failure, these instruments provide the reliability that manufacturers need to maintain their quality standards.

The importance of Mitutoyo calipers extends beyond their basic measurement capabilities. These tools serve as the foundation for quality control processes, helping manufacturers identify variations in their production processes before they become costly problems.

Precise Measurements

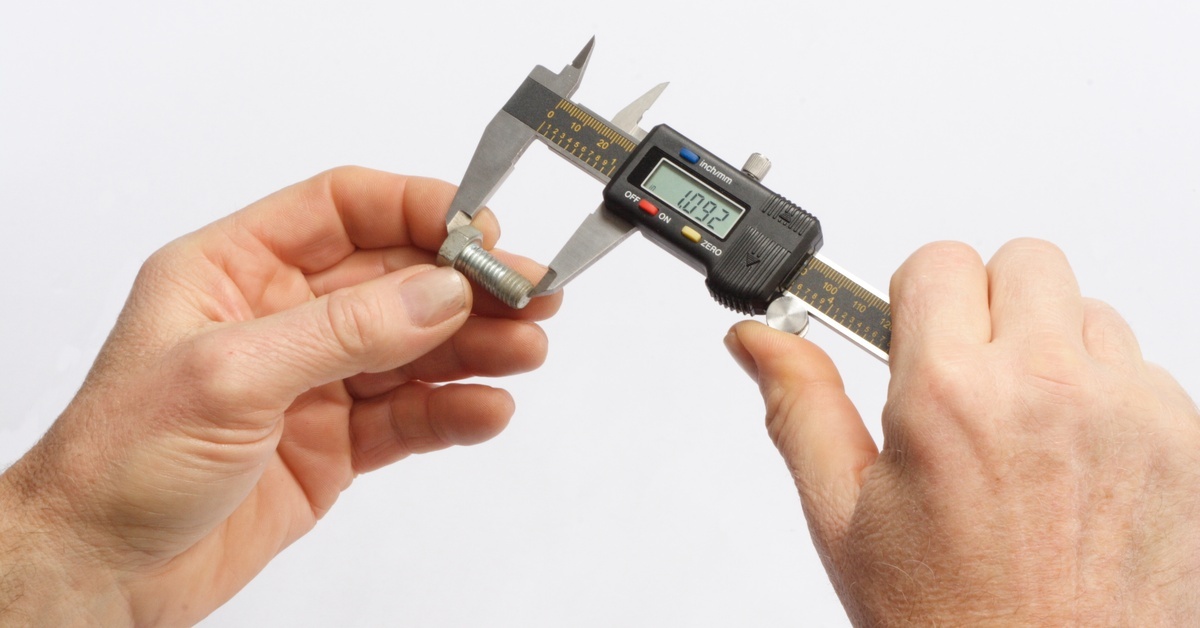

Mitutoyo calipers deliver measurement precision that exceeds the requirements of most manufacturing applications. Their resolution capabilities allow operators to detect variations measured in thousandths of an inch or hundredths of a millimeter, providing the level of detail necessary for modern manufacturing processes.

The instruments maintain their precision over extended periods of use, even in demanding manufacturing environments where temperature fluctuations, vibration, and other factors can affect measurement accuracy. The consistent precision of Mitutoyo calipers means that measurements taken by different operators at different times will yield the same results when measuring identical features. This repeatability is crucial for maintaining quality standards across shifts, production runs, and different manufacturing locations.

Reliable Readings

Reliability in measurement tools means more than just consistency; it creates confidence that each reading represents the true dimensional characteristics of the measured part. Mitutoyo calipers provide this reliability through robust construction and advanced measurement technologies that minimize the impact of environmental factors and operator variables.

The digital displays on Mitutoyo calipers eliminate the interpretation errors that can occur with analog measurement tools. Operators can read measurements quickly and accurately without interpreting scale markings or estimating values between graduations. This clarity reduces measurement uncertainty and improves the overall reliability of quality control processes.

Shop-Worthy Durability

Manufacturing environments present numerous challenges for measurement instruments, including exposure to coolants, metal chips, temperature variations, and physical impacts. Mitutoyo calipers are designed to withstand these harsh conditions while maintaining their measurement accuracy and reliability over extended periods of use.

The construction of Mitutoyo calipers incorporates materials and design features that protect critical measurement components from environmental damage. Sealed electronics resist contamination from manufacturing fluids, while hardened measurement surfaces resist wear from repeated contact with workpieces and fixtures.

Overview of Data Collection Systems

Data collection systems have become essential components of modern manufacturing workflows, serving as the technological backbone that supports quality control, process improvement, and regulatory compliance efforts. These systems capture measurement data from various sources, organize it into useful formats, and provide the analysis capabilities that manufacturers need to make informed decisions about their processes.

The role of data collection systems extends beyond simple data storage. They provide real-time monitoring capabilities that allow manufacturers to detect quality issues as they develop, rather than discovering problems after entire production runs have been completed. This early detection capability can prevent costly scrap, rework, and customer complaints that result from quality problems.

Modern Data Collection Challenges

Data collection isn’t just part of the workflow. It’s a key player in maintaining quality and ensuring modern manufacturing workflows meet requirements. For example, speed requirements in production environments mean that quality checks must be completed quickly without sacrificing thoroughness. Accuracy demands in manufacturing have increased as products become more sophisticated and customer expectations rise. Dependability in quality systems is also crucial for maintaining customer confidence and meeting regulatory requirements.

Integrating Mitutoyo calipers with data collection systems helps manufacturers overcome these challenges. Effective data collection systems fit seamlessly into existing workflows, capturing necessary quality data without slowing production or requiring significant changes to established processes. This ensures speed, accuracy, and dependability without creating bottlenecks or pulling resources away from other steps in the workflow.

The Benefits of Integrating Calipers With Data Collection Systems

When you can automatically connect your digital calipers to your data collection, you eliminate the time-consuming manual processes that traditionally separate measurement activities from data analysis and record-keeping functions. When measurement data flows directly from calipers into data collection systems, operators no longer need to manually record readings or transfer information between different systems. This direct data transfer eliminates transcription errors and ensures that the data used for analysis accurately reflects the actual measurements taken.

Furthermore, real-time data availability transforms quality control from a reactive process into a proactive management tool. Operators and supervisors can monitor quality trends as they develop, identifying potential problems before they result in out-of-specification parts. This early warning capability enables corrective actions that prevent quality problems rather than simply detecting them after they occur.

Statistical process control capabilities become more powerful when supported by integrated measurement and data collection systems. The continuous flow of measurement data enables sophisticated statistical analyses that can reveal subtle process variations and trends that might not be apparent through manual data collection methods.

Easy Data Collection With SPC Gage Interfaces

Advanced Systems and Design’s multi-input gage interfaces represent a significant advancement in measurement data collection technology. They provide the connectivity and processing capabilities necessary to integrate precision instruments like Mitutoyo calipers with comprehensive data collection systems. These interfaces serve as the bridge between measurement instruments and data management systems, handling the technical aspects of data transfer and formatting.

Plug-and-play functionality in modern gage interfaces eliminates many of the technical barriers that previously made integration projects complex and time-consuming. Manufacturers can connect Mitutoyo calipers to data collection systems without extensive programming or system configuration, enabling rapid implementation of integrated measurement solutions.

The seamless integration provided by these interfaces allows operators to continue using familiar measurement procedures while benefiting from automated data collection. The interfaces work transparently, capturing measurement data without changing established measurement techniques or operator training.

When you need a solution that boosts efficiency, maintains accuracy, and keeps your operation running smoothly, Advanced Systems and Designs can help. Enhance your precision instrument data collection when you shop our Mitutoyo digimatic calipers and data collection solutions today.