Accurate measurements are the backbone of successful projects, whether you’re working in manufacturing, engineering, or any technical field requiring precision. Calipers are essential tools, revered for their ability to provide unparalleled accuracy in measurements.

However, maintaining a caliper’s accuracy isn’t as simple as using it and setting it aside. Regular maintenance and proper calibration are vital to ensuring long-term performance. This guide will help you understand how to extend caliper accuracy through regular maintenance and correct calibration.

Understanding Calipers

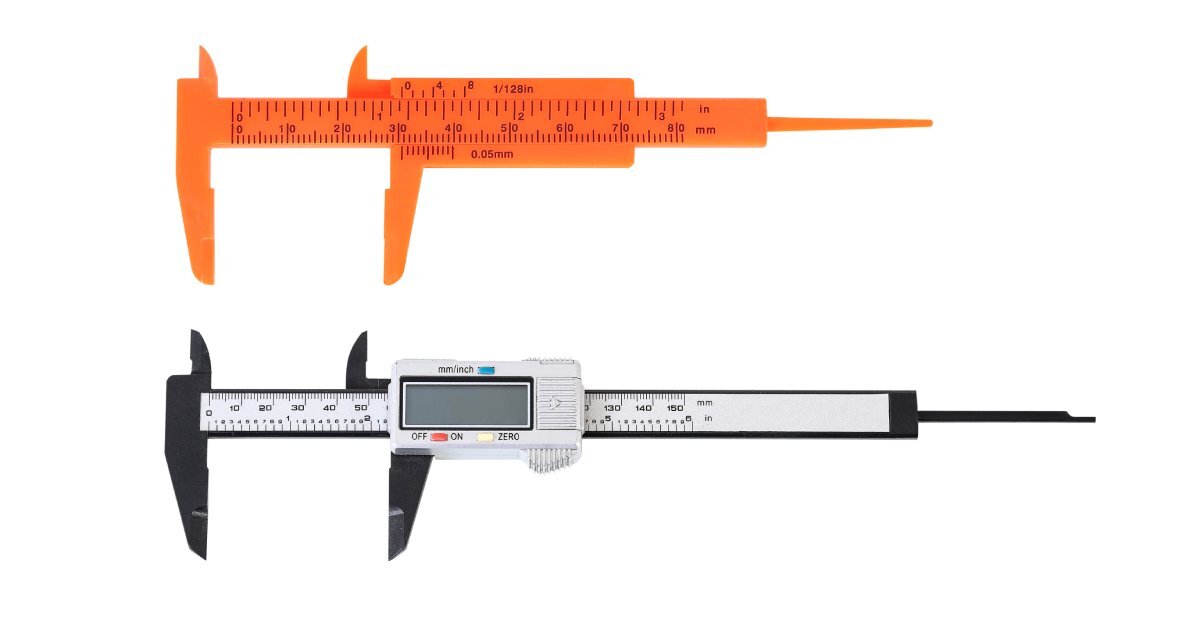

Calipers are precision instruments available in various types, such as digital, dial, and vernier calipers. Choosing the right type is crucial since each has unique features and applications that affect your readings. Digital calipers are recognized for their ease of use and ability to display measurements instantly. Dial calipers work without the need for a battery, making them reliable for extended use in environments where digital tools might fail. Vernier calipers, the classic choice, rely on manual reading.

When selecting a caliper, consider your specific needs. If you are dealing with tasks that require highly intricate measurements, investing in a reliable and precise caliper is a must. Prioritize quality over cost; a subpar caliper can produce inconsistent results, leading to errors in your work. Remember that precision is non-negotiable in any field that relies on accurate measurements. By choosing the right caliper, you take the first step toward ensuring reliable performance.

Regular Cleaning

Keeping your caliper clean is essential for maintaining its accuracy. Dust, debris, and even fingerprints can impact the precision of your tool. A simple yet effective cleaning routine can prevent long-term issues. Start by using a soft, lint-free cloth to wipe down the caliper after every use. Pay extra attention to the jaws and internal mechanisms, as dirt and particles can easily accumulate in these areas.

For a deeper clean, consider using a mild cleaning solution that’s safe for delicate tools. Apply the solution to a cloth rather than directly onto the caliper to avoid excessive moisture exposure, which could lead to corrosion. Ensure the caliper is thoroughly dried after cleaning to prevent any water from lingering in the components. Consistently following this process will keep your caliper operating at its best and protect it from unnecessary wear.

Proper Storage Techniques

Poor storage practices are some of the most common culprits behind caliper inaccuracies. Calipers are delicate tools that require thoughtful storage to remain in good shape. Never toss your caliper into a toolbox or leave it exposed on a workbench where it might suffer damage. Instead, use a dedicated storage case specifically designed for calipers. Many quality calipers come with their own storage cases, which offer both physical protection and insulation from environmental factors.

Keep your caliper in a dry, temperature-stable environment. Fluctuations in humidity or temperature can cause expansion or contraction in the materials, eventually compromising accuracy. Avoid storing your caliper near magnets, as this can interfere with the instrument’s operation. A bit of extra care with storage goes a long way in preserving the functionality of your tool.

Calibration Basics

Calipers must be calibrated regularly to maintain their high standard of accuracy. Calibration ensures the tool measures as precisely as it did when it left the factory. But when should you calibrate? A good rule of thumb is to calibrate your caliper as often as the frequency and intensity of its use demand. For tools used daily or in especially demanding tasks, more frequent calibration is a smart choice.

Start by using a standard calibration block, also known as a gauge block, which provides a precise point of reference. Place the caliper against the block and make sure it reads zero at a fully closed position. If it doesn’t, adjust the tool before proceeding further with other measurements. Always give calibration tools the same care and attention as the caliper itself to ensure accurate results every time. Proper calibration is not just a procedure; it’s an ongoing practice that plays a critical role in maintaining your caliper’s functionality.

Common Calibration Issues and Solutions

Even with routine calibration, occasional issues may arise that compromise your caliper’s performance. One common problem is a zero error, where the caliper doesn’t display zero when fully closed. This can be resolved by resetting the calibration or adjusting the calibration setting in digital models. For vernier or dial calipers, manual adjustments to the zero point may be necessary.

Another issue to watch out for is lead error, which refers to inaccuracies caused by wear or improper alignment of the jaws. Regular maintenance, including periodic checks on jaw alignment, minimizes the risk of lead error. Lastly, accumulated dirt or residual oil can lead to inconsistent readings. Ensuring your caliper is clean and well-maintained solves this issue effectively. Being proactive about potential problems can prevent inaccuracies from snowballing into costly or time-consuming mistakes.

Optimized Data Collection

Regular maintenance and calibration only go so far in extending caliper accuracy. You also need to ensure accuracy in your data collection. With the right solutions, you can connect your digital calipers directly to your computer, laptop, or tablet, allowing you to automatically record measurements without manual entry. This feature eliminates human error and accelerates data analysis.

Using single- or multi-input gage interfaces from Advanced Systems and Designs, you can connect your caliper directly to computers or compatible devices, streamlining your workflow significantly. The plug-and-play design allows you to incorporate optimized data collection into your workflow right away, making it easy to improve your data collection and ensure accuracy across your records.

This feature is particularly beneficial for projects requiring extensive measurements or real-time logging. With the right setup, you can create organized data logs that are easy to access, analyze, and share. Investing in these interfaces not only optimizes your time but also increases the accuracy and reliability of your measured data. Leveraging technology in tandem with manual expertise takes your measurement practices to the next level.

Ensuring Long-Term Accuracy

Maintaining and calibrating your caliper might require consistent effort, but the benefits far outweigh the time investment. Remember, accurate measurements lead to precise results, and that precision is what sets apart good work from mediocre work. Make the most of your tools when you shop Mitutoyo Absolute digimatic calipers and other precision measurement solutions at Advanced Systems and Designs today.